Finishing System

-

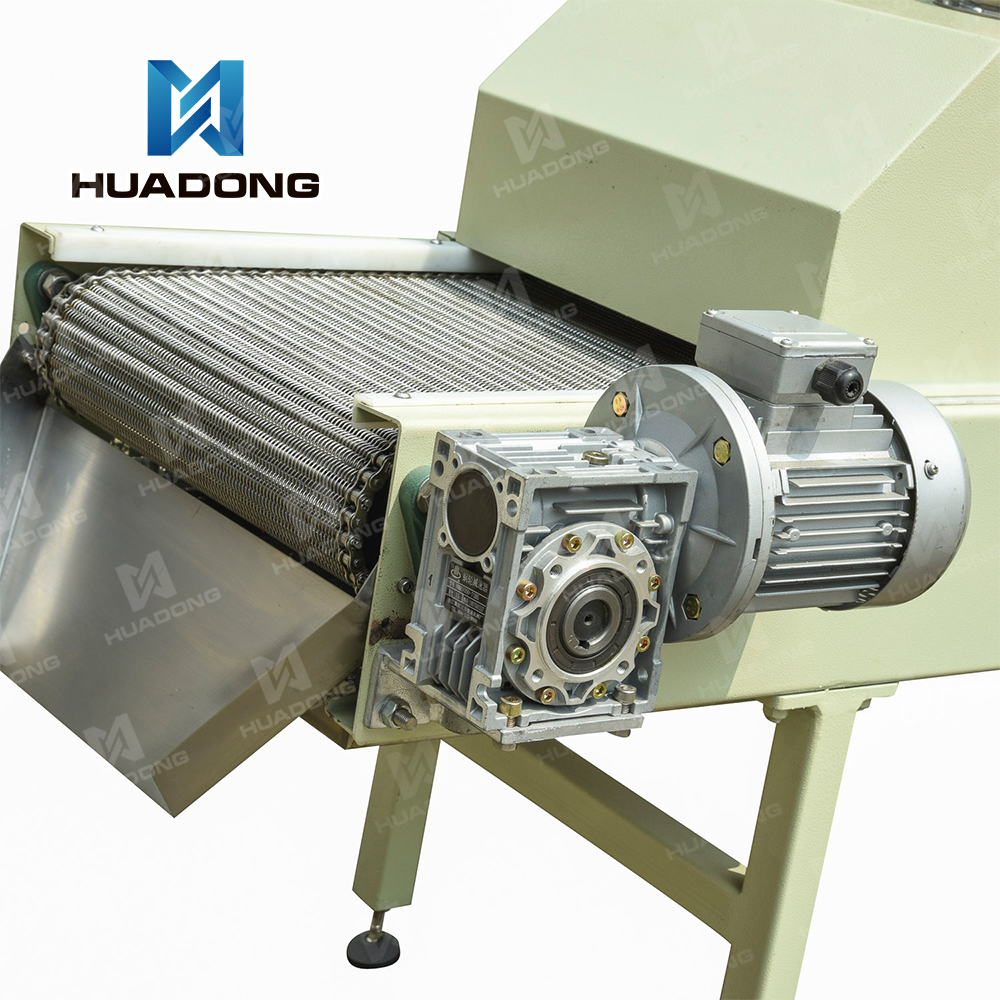

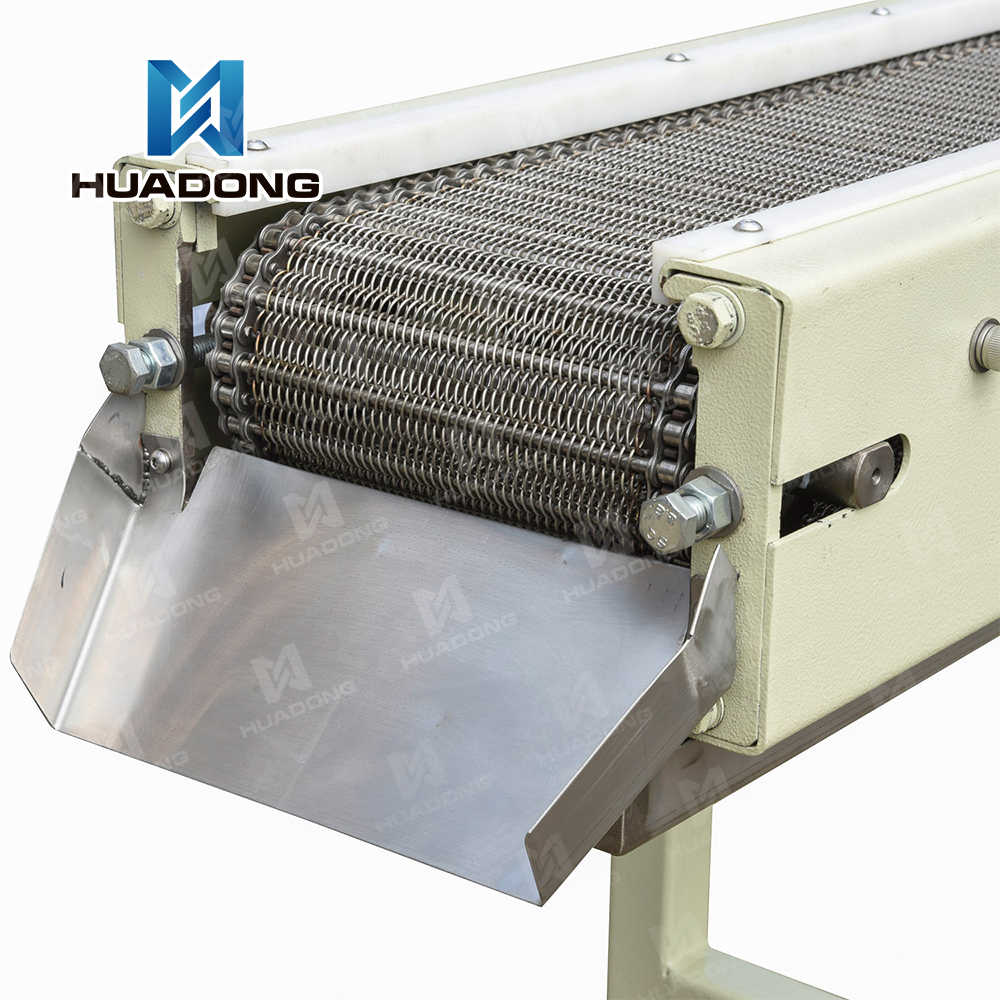

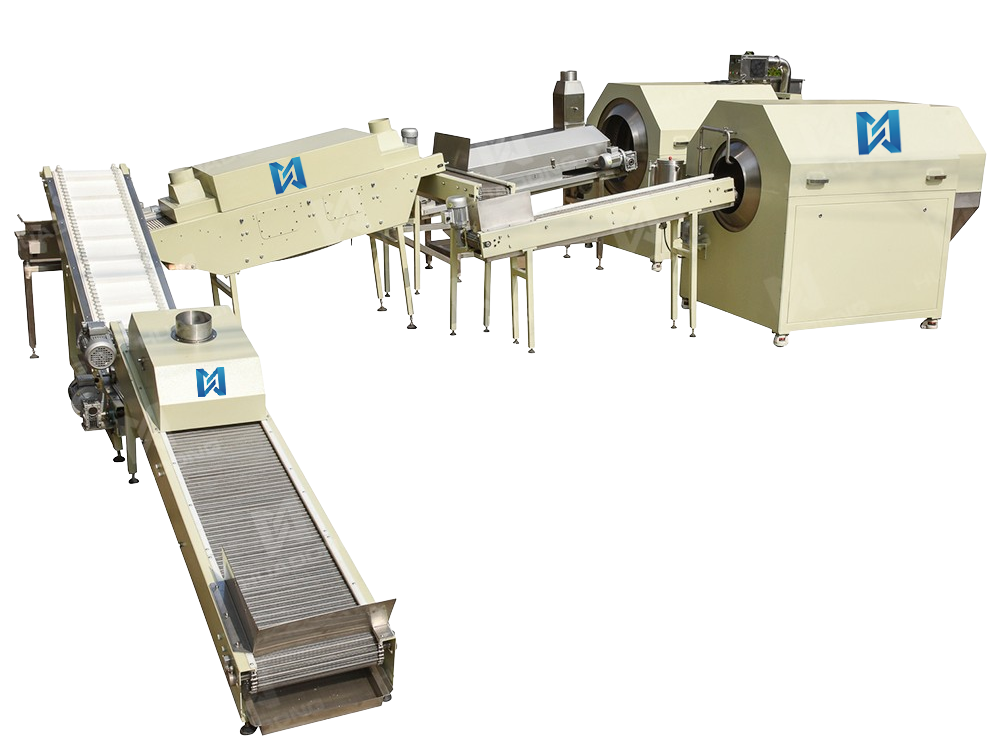

Demoulding Conveyor

This conveyor used to convey gummy from depositing machine to Oil /sugar coater after demoulding. It use stainless steel for frame and SS304 for the part which will contact with gummy.

-

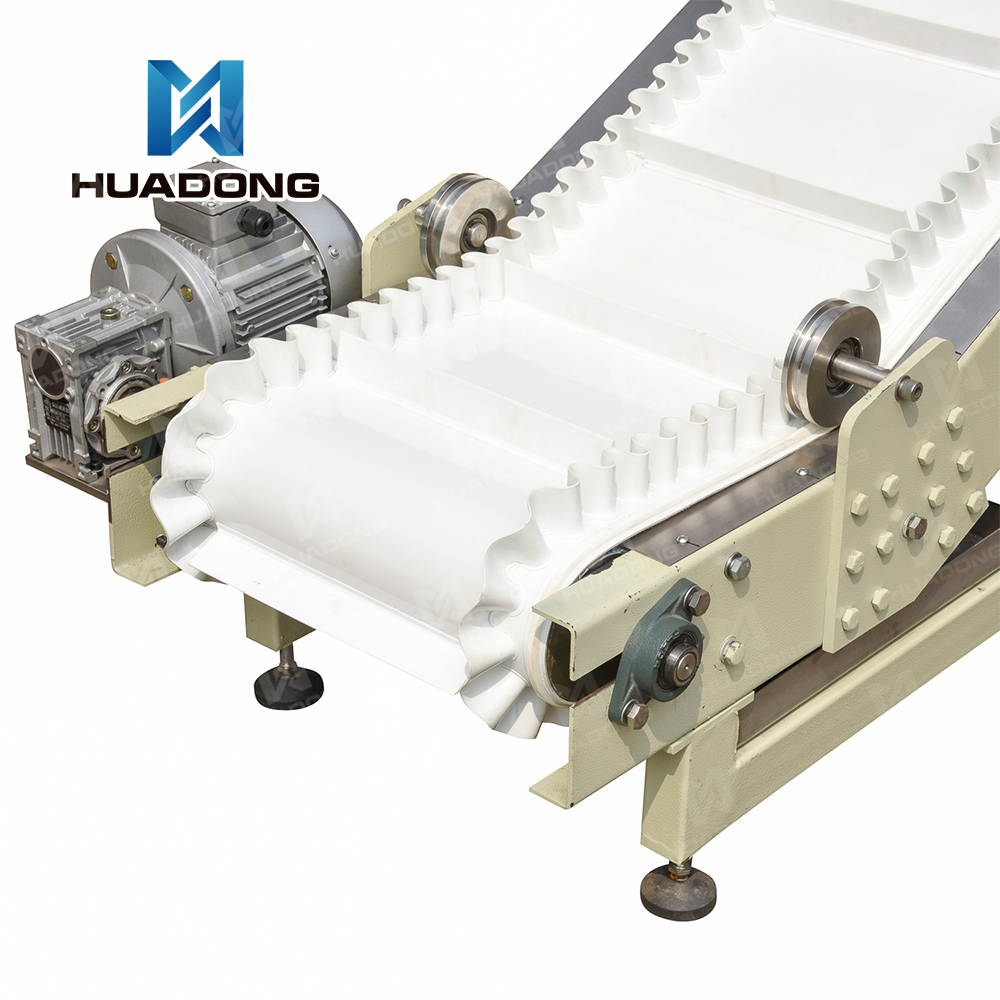

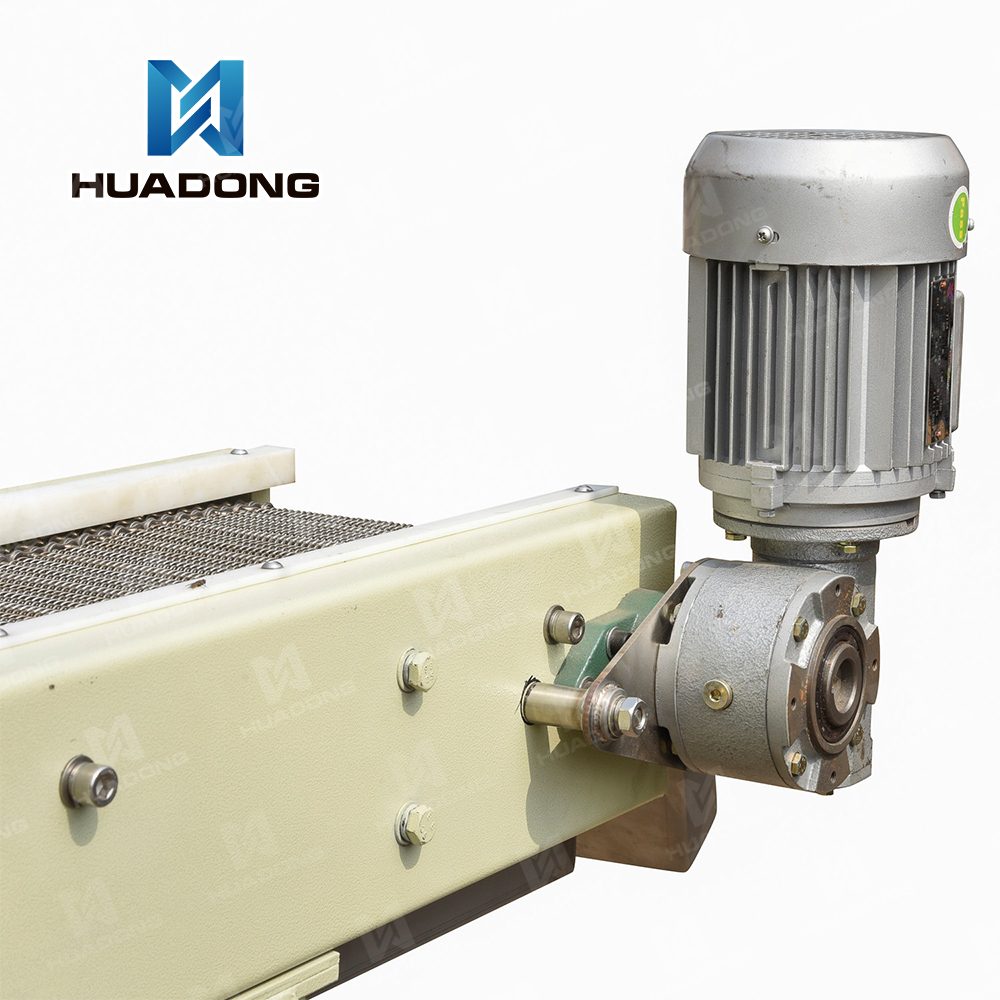

Lifting Conveyor

This conveyor used to convey gummy from conveyor after demoulding to transport conveyor transfer conveyor. It use stainless steel for frame and SS304 for the part which will contact with gummy.

-

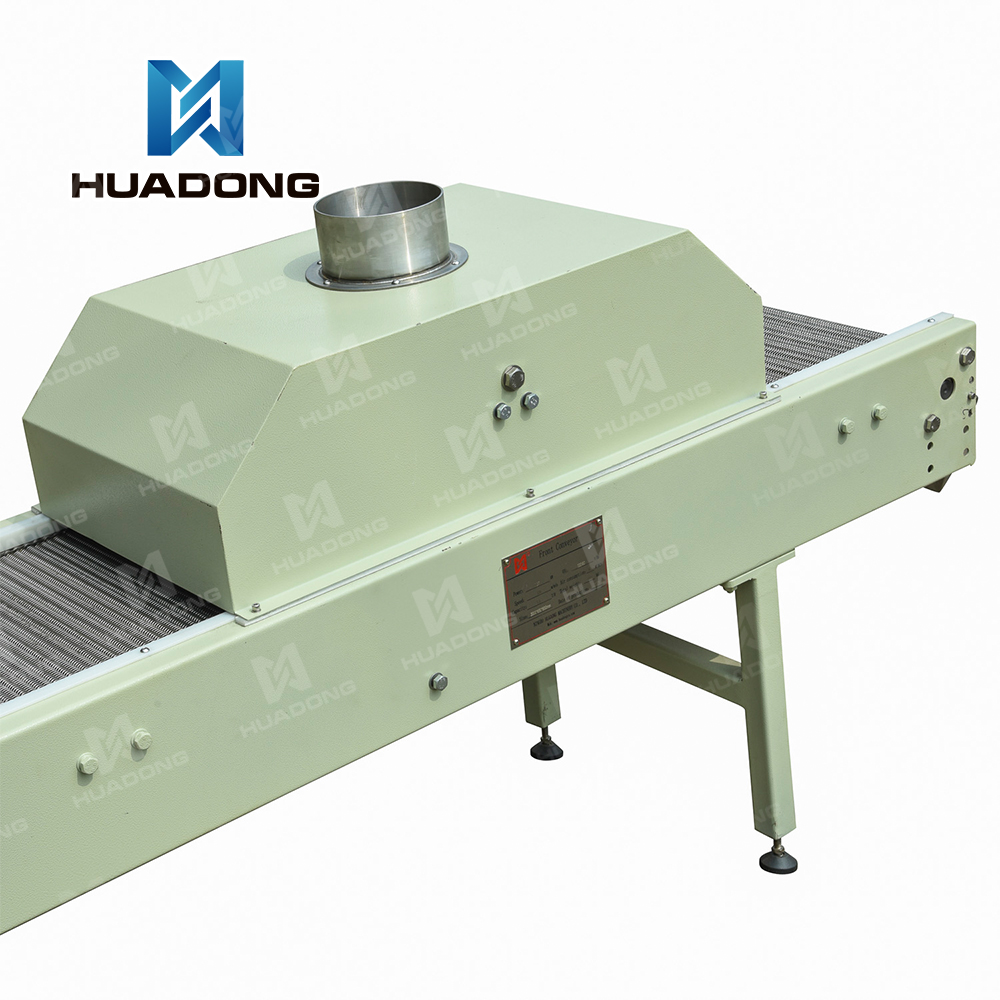

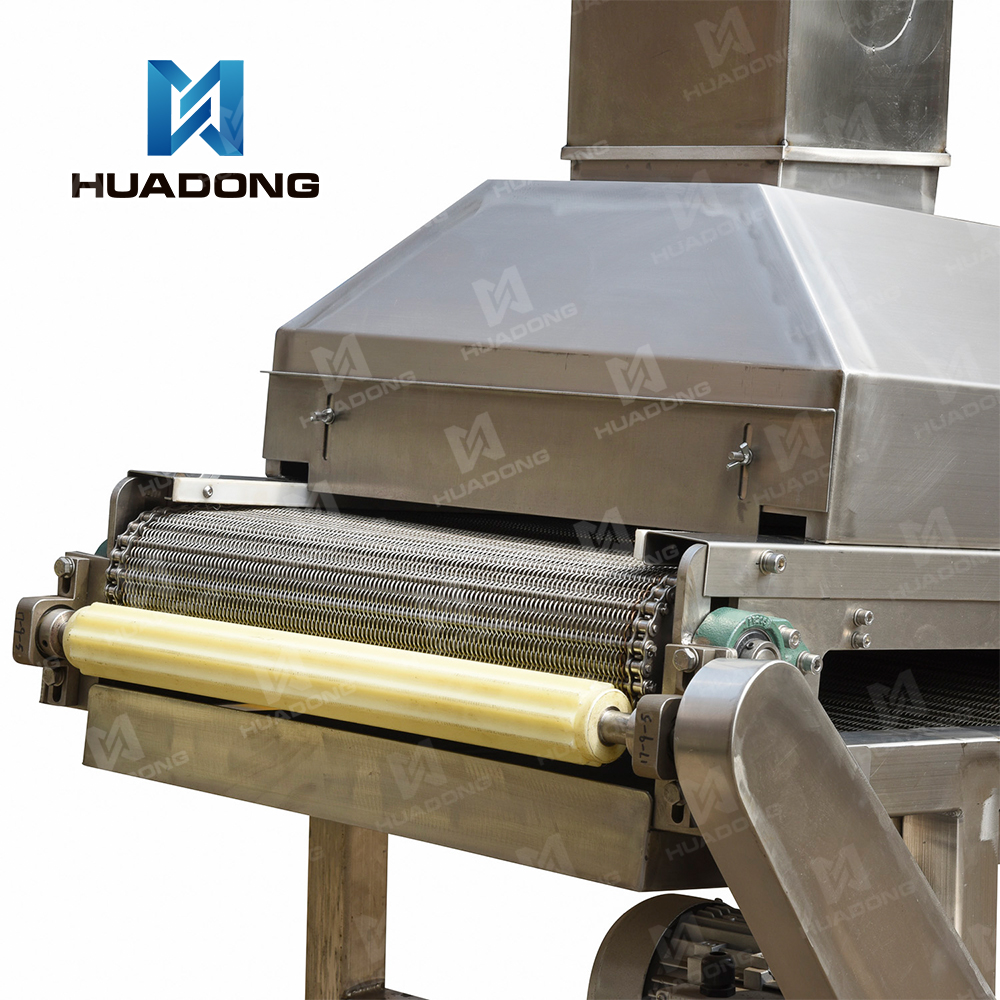

Starch cleaner

Function: convey finished candy to remove starch. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

-

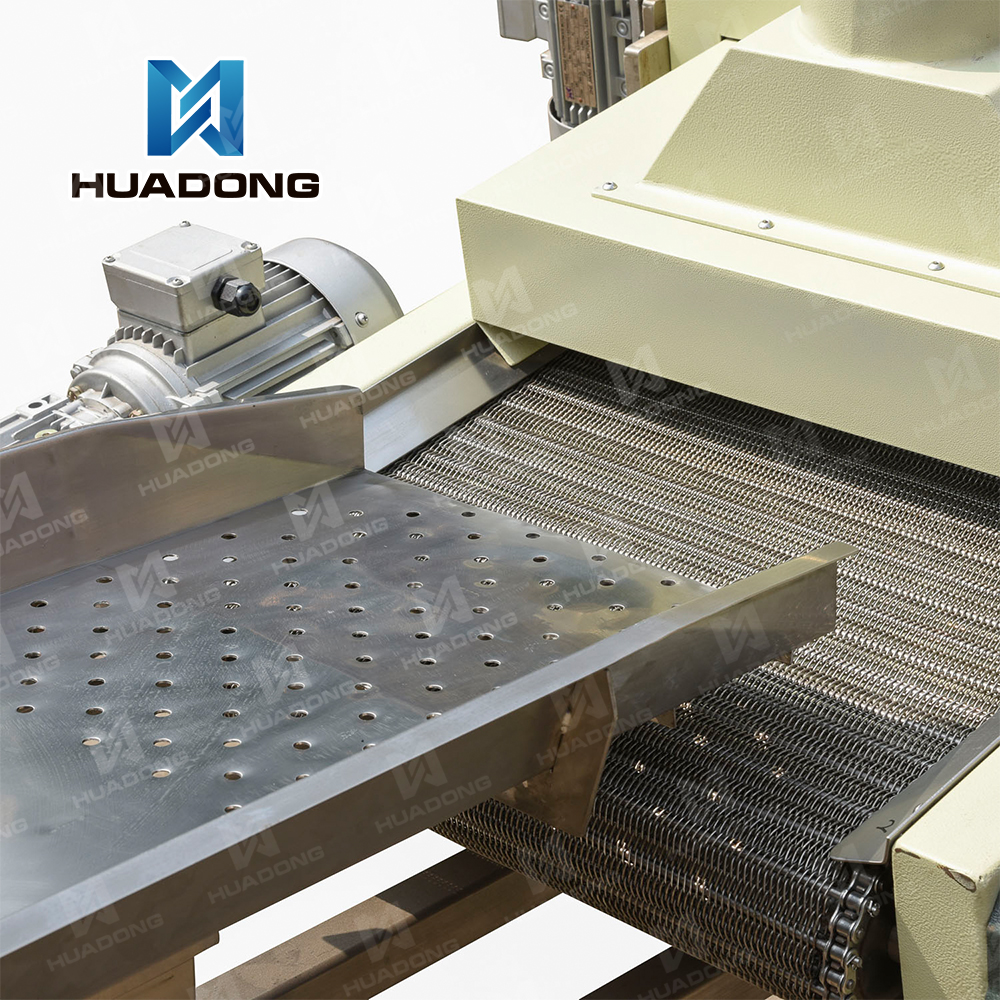

Transfer conveyor

This conveyor used to convey gummy from depositing machine to Oil /sugar coater after demoulding. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

-

Oil conveyor

Function: convey candy to oiling. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

-

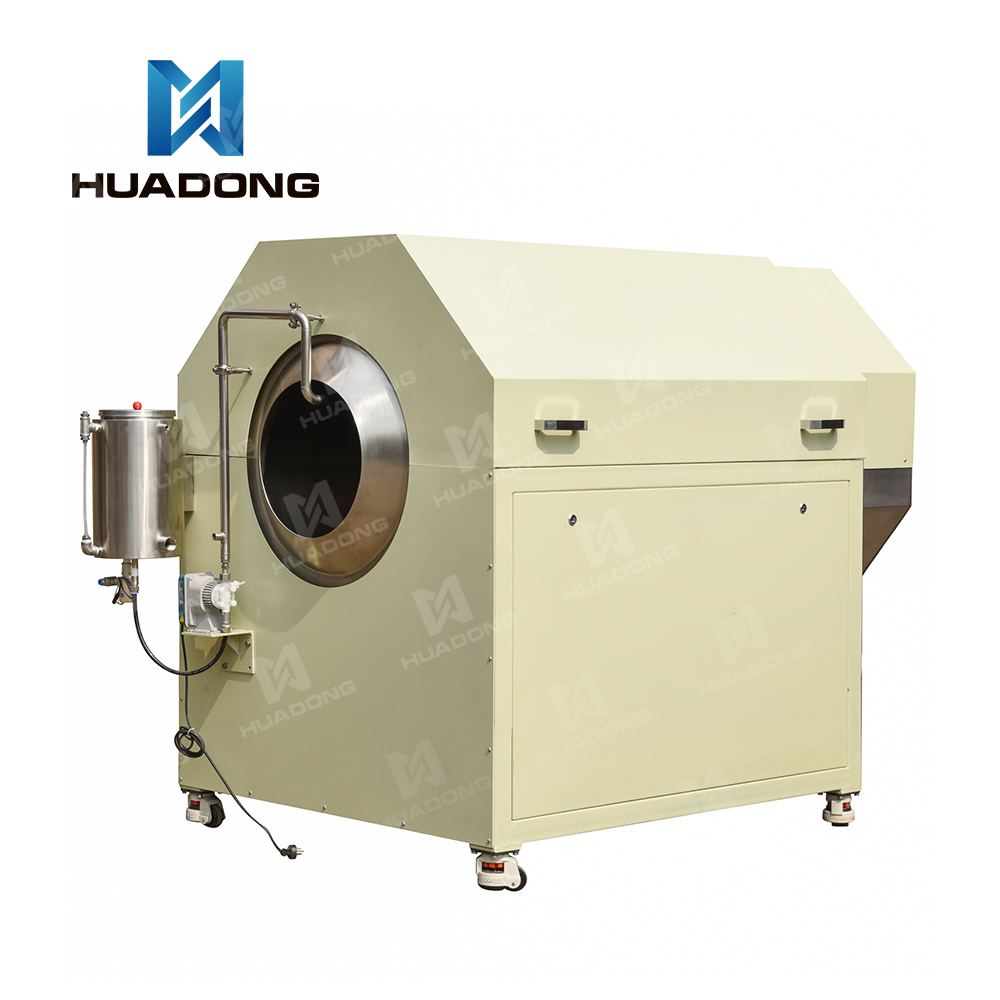

Oil coater

Function: oiling for finished jelly candy. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

-

Steam humidifier

Function: After starch clean, use it to wet candy for coating sugar. It use stainless steel for frame and SS 304 for the part which will contact with gummy.

-

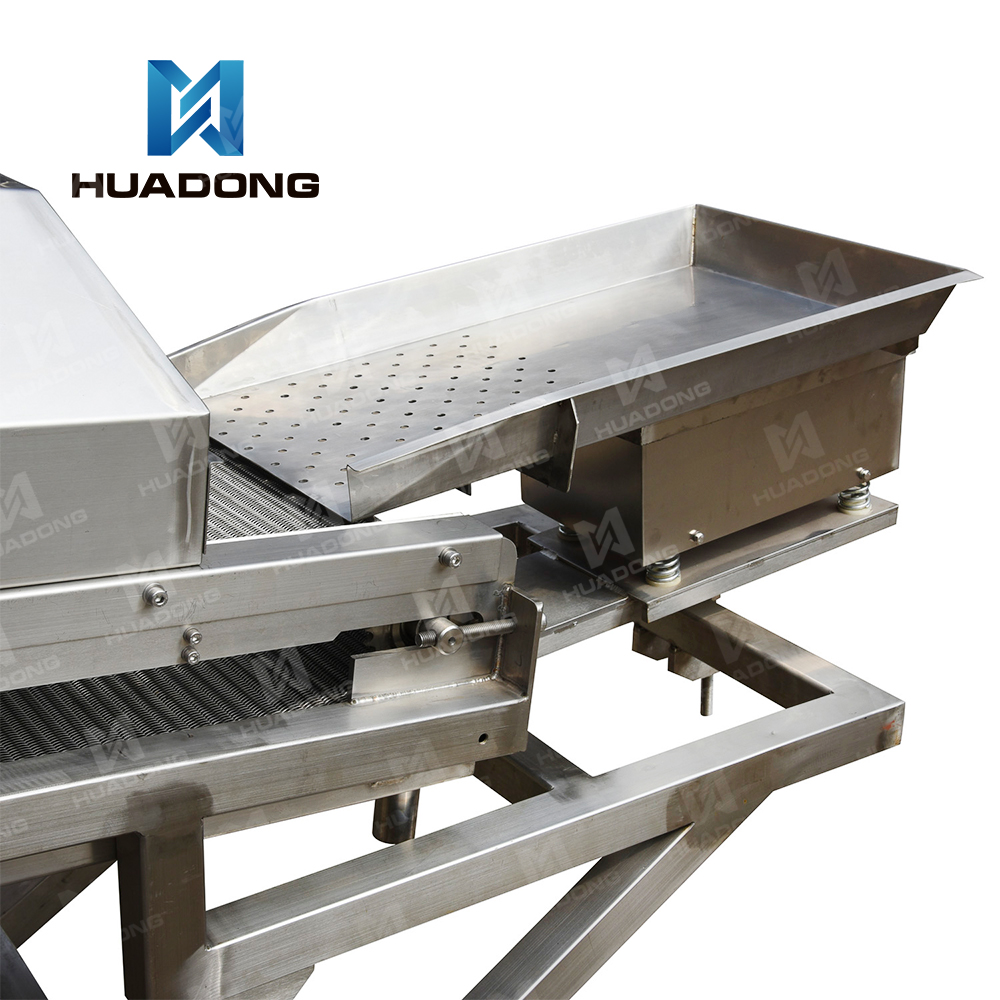

Sugar sander

Function: After steaming heating, coat sugar on candy, It use stainless steel for frame and SS 304 for the part which will contact with gummy.

For more information, please email or call our 24-hour hotline.

- cali@huadongcn.com

- +86-13429390286

Copyright ©2026 Ningbo Huadong Machinery Co., Ltd. All Rights Reserved.